The world of maritime transportation is a diverse and complex one, with various ship types designed to perform specific tasks and meet unique transportation needs. Right now, we will explore some of the most common ship types, each with its own distinctive characteristics and purposes.

Cargo Ships

Cargo ships are the workhorses of the maritime industry, designed to transport goods and commodities across the world's oceans and waterways. They come in different categories, including container ships, bulk carriers, and general cargo ships, each optimized for specific cargo types and volumes.

Tanker Ships

Tanker ships are specialized vessels used for transporting liquid cargoes, such as crude oil, petroleum products, chemicals, and liquefied natural gas (LNG). They play a crucial role in the global energy trade and are categorized based on the type of cargo they carry, including oil tankers, chemical tankers, and LNG carriers.

Passenger Ships

Passenger ships are designed to carry people, whether for leisure, tourism, or daily commuting. These ships vary in size and purpose, ranging from large cruise liners and ferries to smaller coastal passenger vessels.

Container Ships

Container ships are specifically designed for transporting standardized cargo containers. They are essential for the global logistics chain, enabling efficient and secure transportation of goods in containers of various sizes.

Bulk Carriers

Bulk carriers specialize in transporting loose, dry bulk cargoes, such as coal, minerals, grains, and ores. They come in different sizes, from Handysize to Capesize, each suited for specific cargo volumes and routes.

Fishing Vessels

Fishing vessels are used for commercial fishing operations, ranging from small trawlers to large factory ships equipped with processing facilities. They play a critical role in the global seafood industry.

Research Vessels

Research vessels are equipped with specialized equipment and laboratories for scientific research in fields such as oceanography, marine biology, and geology. They contribute to our understanding of the oceans and marine ecosystems.

Tugboats and Towboats

Tugboats and Towboats provide towing and assistance services to other vessels, helping them maneuver in harbors, navigate through narrow channels, and tow barges.

Naval and Military Vessels

Naval and Military vessels are used by the armed forces for Defense and Security purposes. They include Aircraft Carriers, Destroyers, Submarines, Fregat, Cruiser, Corvette, Patrol Boats, etc

Yachts and Pleasure Craft

Yachts and pleasure craft are recreational vessels used for cruising, sailing, and water sports. They come in various sizes, from small sailboats to luxury superyachts.

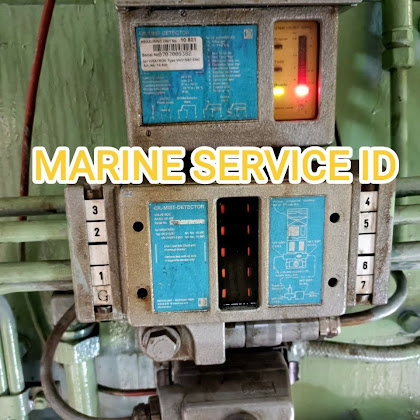

Indonesian Marine Services MARINE SERVICE ID

For Business Inquiry, please click the following link :

Reprogramming,Maintenance,Repair,Troubleshooting,Annual Certification & Calibration Services

Various of Electronics P.C.B. Boards

Various Types of Ship Systems Installation, Wiring & Termination

Boiler & Generator Controller and Generator AVR

Bilge Floats, Level Gauge

Relay, Indicators, Panels

Navigational Panels Light

Temperature Controller & Transmitters, RTD Sensor, Thermometer

Fixed & Portable Gas Detectors, Oxygen Analyzers,Spare Kits & Span Gas

Vapour Alarm Systems & Fire Alarm Systems

Pressure Transmitter, Gauges. Pneumatic Pressure Transmits, Pressure Switch

Test Pump and Gauges

Valve Solenoid & Valve Positioner

Engine Telegraph Unit (ETU)

Gas Analizer and Gas Alarm Monitor Control

Ullage Temperature Interface / UTI Meter

Flow Meter

Portable Multi Gas Detectors and Portable Single Gas Detectors

Fixed Gas Detection Systems

Fixed Gas Sampling Systems

Pump Room Gas Detection Systems

Temperature Calibrator & Pressure Calibrator

Multimeter, Thermometer and Alcohol meter

Pressure Gauges & Transmitters

Engine Control Room Alarm Monitor & Control / ECR

Cargo Control Room Alarm Monitor & Control / CCR

Engine Protection & Safety Devices

Engine Temperature & Pressure Alarm Monitoring and Control

Engine & Atmospheric Oil Mist Detection

Incinerator

Engine RPM Indicator

Engine Remote Control

Engine Temperature Control System

Exhaust Gas / Engine Thermometer

Supply & Installation Services

Bilge Alarm Monitor for 15ppm OWS Oily Water Separator

Oil Discharge Monitor Equipments ODME

Tank High Level Alarm

Tank Overfill Level Alarm

Tank High High Level Alarm

Vapour Pressure Alarm System & Monitor Control

Span Gas for Gas Calibration

For our other Technical Services, please Visit the MARINE SERVICE ID Blogs :

Ship Annual Calibration & Certification Services